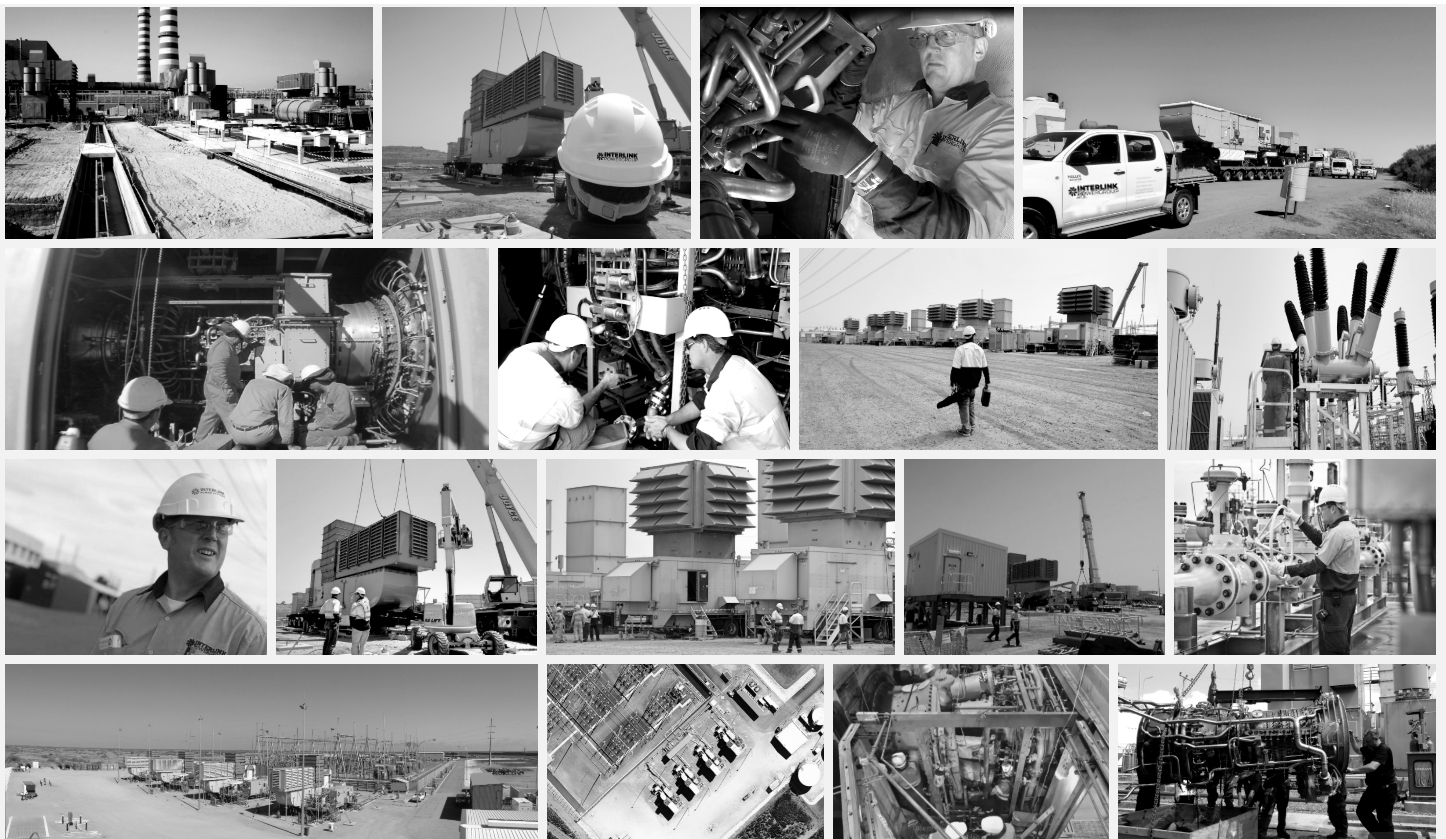

By partnering with Interlink Power, clients can rest assured that their projects will be completed safely, efficiently, and with minimal disruption to local communities and ecosystems.

In addition to Interlink’s expertise in addressing design concerns and overcoming challenges in traditional project settings, Interlink Powers’ team is also adept at tackling the unique complexities associated with mobile gas turbine installations in remote and challenging locations.

Operating in remote and challenging environments presents a host of logistical, technical, and environmental obstacles that require specialized knowledge and skills to navigate. From rugged terrain and extreme weather conditions to limited access to infrastructure and resources, these locations demand a strategic approach and meticulous planning to ensure the successful installation and operation of mobile gas turbines.

One of the key challenges of installing mobile gas turbines in remote locations is the lack of existing infrastructure and support systems. Unlike conventional power plants, which are typically situated near established transportation networks and utilities, remote locations often lack the necessary infrastructure to support large-scale installations. This can include everything from access roads and utilities to fuel supply chains and maintenance facilities.

To address these challenges, Interlink Powers’ team leverages our extensive experience in remote project management and logistics coordination. We work closely with clients to assess site conditions, identify potential obstacles, and develop comprehensive plans to mitigate risks and streamline operations.

In some cases, installing mobile gas turbines in remote locations may require innovative solutions such as modular design and pre-fabrication. By pre-assembling components off-site and transporting them to the installation location, Interlink Power can minimize on-site construction time and reduce the logistical challenges associated with remote projects.

Once installed, operating mobile gas turbines in remote locations presents its own set of challenges. Maintaining reliable power generation in isolated environments requires robust monitoring and control systems, as well as contingency plans for emergencies and equipment failures. Ensuring compliance with environmental regulations and community standards is essential for maintaining the trust and support of local stakeholders.

Interlink Powers’ team excels at implementing comprehensive monitoring and maintenance protocols to ensure the reliable operation of mobile gas turbines in remote locations. By leveraging remote monitoring technology and predictive maintenance algorithms, they can proactively identify potential issues and address them before they escalate into costly downtime or operational disruptions.

By partnering with Interlink Power, clients can rest assured that their projects will be completed safely, efficiently, and with minimal disruption to local communities and ecosystems.